Do you want to improve your business without stress and problems?

We have the right solution for you: our complete "Turnkey" Bottling Lines

YOU WON’T HAVE TO WORRY ABOUT A THING, WE’LL TAKE CARE OF EVERYTHING.

Do you only have a small footprint or specific technical needs? Do you have a well-defined budget? We offer you a complete service ranging from consultancy to testing and continuous after-sales assistance.

There is only one goal – to provide you with a high-performance and reliable bottling line, always guaranteeing the highest quality of your final product.

HIGH PERFORMANCE BOTTLING LINES SUITABLE FOR ANY KIND OF PRODUCT, BOTTLE AND CONTAINER

We have been supplying complete bottling plants all over the world since 1993.

Framax can supply bottling lines to suit a wide range of products such as mineral water, carbonated soft drinks, wine, beer, edible oils, mixed alcoholic beverages, liqueurs, fruit juices etc., into traditional or modern packaging, such as bottles made of Pet, Pen, Glass, HDPE, cans, bag-in box-etc.

We'll deliver the right solution for you!

Custom designed

We study the best solution based on your technical needs, available space and budget.

Simple to use

After basic training you will be able to produce with maxium output.

Superior Quality

The original characteristics of your product will not be altered throughout the bottling and packaging process.

Reliable over time

The high quality materials and components with which they are built are a guarantee of absolute reliability.

Fast delivery times

We guarantee delivery as fast as possible without ever compromising the final quality of the project.

Non-Stop Assistance

Quick and effective technical support also on site, thanks to a network of representatives appointed in different countries of the world. Technicians and consultants always available remotely thanks to Industry 4.0 technology.

Economically advantageous

Best quality / price ratio on the market. All without compromise! Energy-Saving Technology.

Why choose FRAMAX and not other solutions?

(Spoiler: because we take care of everything ... scroll down for details)

Thanks to the many types of liquid that can possibly be treated (water, beer, wine, fruit juices, energy drinks, etc.), the beverage market is certainly an attractive sector to invest in.

However, getting into the Beverage business is not at all easy. There are many aspects that you will have to face and not least, is the technical one.

- Designing a bottling line optimized for your needs, both in terms of production and budget, is not easy: choosing the right technologies and machines for your production is a delicate operation, but of the utmost importance.

- Ensuring that all the machines that make up the bottling line interact correctly with each other, even from different manufacturers, is essential. This will lead to high-performance production and will avoid unnecessary downtime, stress and frustration.

THE BEVERAGE PACKAGING MARKET IS FULL OF MANUFACTURERS OFFERING PARTIALLY COMPLETE SOLUTIONS OR SOLUTIONS OF DUBIOUS RELIABILITY.

Over time, given their complexity, any bottling plant can develop problems due to the most varied reasons and often, to solve them, there is the risk of having to contact multiple supplier companies with the result of having repeated downtime and production stops.

Do you want to start on the right foot? Then think carefully to whom to entrust the future of your business.

Simple ... because we take care of everything!

All over the world, for 30 years, we have been supporting entrepreneurs and sector operators like you in all phases of their business project in the beverage sector: from planning, to production, installation, start-up, to commissioning and after-sales assistance.

- All of our bottling lines, as well as the machines integrated into them, are tailor-made with the most modern technology with the primary objective of always protecting and guaranteeing the quality of your product.

- The integration between the various machines that make up the bottling line, including those from different manufacturers, is completely performed by FRAMAX and the responsibility will always be ours.

Thanks to Industry 4.0 technology our technicians and consultants will always be available remotely. Furthermore, FRAMAX has partners in various countries around the world who ensure continuous assistance even on site.

Finally you can give life to your business project with complete peace of mind!

OUR SOLUTIONS

We “know how”

We provide a 360 ° service for complete bottling lines: from design to packaging.

Project Planning & Engineering

The main key to our success is the capability to offer customers a complete tailor-made solution according to specific technical requirements, starting from the initial budgetary proposal to the final project plan designed to fit within the space availability but also to fit the required budget, always keeping in mind the importance of looking after the product to be packaged.

Primary objective is in fact to care about “THE PRODUCT”, making sure that its original characteristics are not altered throughout the bottling & packaging process.

Conveying, Handling, Packaging & Automation

Line control automation is programmed according to each specific product and packaging configuration, providing coordinated interaction between each system component to ensure maximum efficiency even in case of packaging several different types of products.

- Automation & Control

Our production lines start from the empty container line feeding right through to package conveyors at the end of the line. - Depalletising and Palletising systems

- Secondary packaging

An important process common to most products in the food and beverage industries is packing containers into clusters, crates, shrink wrapped bundles or cartons. Specific packing machines are supplied to suit the numerous shapes and sizes of products to be packed as well as the different packaging configurations.

Beverage Production & Process Technologies

Framax supplies complete Know-How for the processing of semi-processed raw materials to the finished product, as well as various processing equipment suitable for different applications.

- Syrup plants

- Premix units for soft drinks and carbonated soft drinks preparation

- Mineral water carbonating system

- Blending equipment

- Deaeration systems

- Homogenizing

- Flash pasteurisation

- CIP (cleaning-in-place) and SIP (sanitizing-in-place) systems

- Disinfecting solutions preparation • UV-light (ultraviolet) disinfecting systems

- Mineralization and aroma dosing plants

- Water ozonising plants and ozone generators

- Sand and active carbon filtering systems

- Membrane filtering plants (reverse osmosis)

- Cartridge filtering systems

- Processing equipment for food and beverage industry

- Special custom-made applications

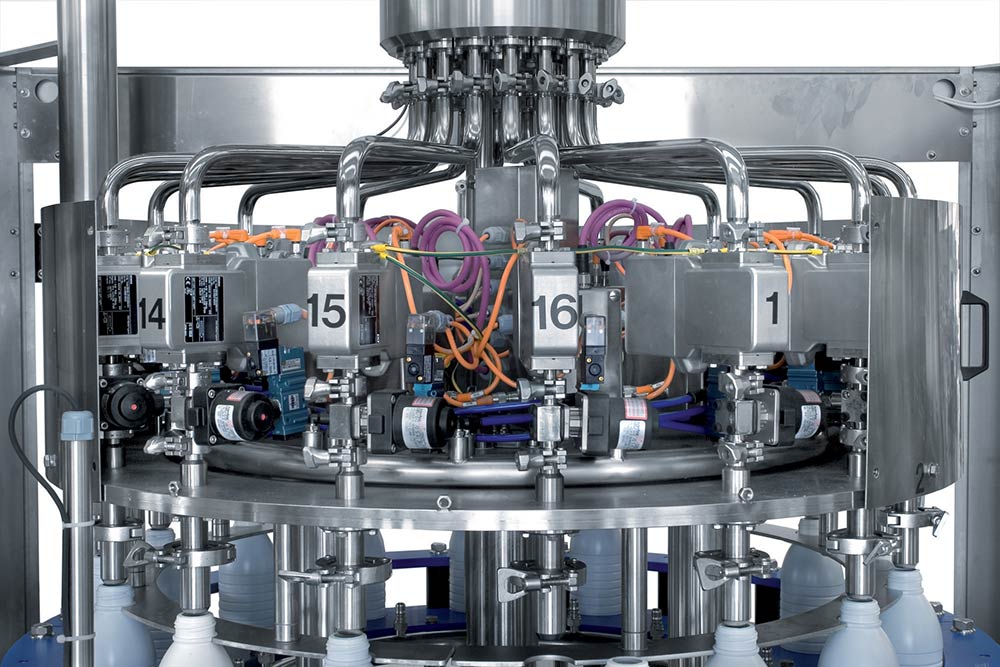

Beverage filling technologies

Whilst keeping in mind the importance of caring about the product sensitivity to external contamination, Framax Beer filling technology utilizes the traditional isobaric (counter-pressure) multi-pre-evacuation system for glass or aluminium bottles and specific filling systems designed to fill beer into PET, cans and kegs.

Depending on the beer type and customer needs the supply may include product treatment equipment such as flavour mixing, flash or tunnel pasteurisation, followed by the preferred labelling solution, packaging into cluster packs, cartons, shrink film and finally palletising.

Filling systems are typically low vacuum-gravity for flat wines & counter-pressure filling for both flat and sparkling wines, closures with natural or synthetic corks, screw caps, mushroom corks & wire-hoods, depending on the specific packaging requirements.

The product is thoroughly protected by vacuum air removal and inert gas saturation of the empty bottles as well as the caps and the bottle neck headspace.

An extensive range of filling valve designs are available according to the specific product characteristics, filling system, bottle types and customer requirements, thus ensuring product protection and efficiency.

Complete lines for glass and PET bottles, filling with counter-pressure, gravity or flowmeter system (non-contact filling), with various options available to ensure the maximum product safety and “Ultra Clean” environment such as Laminar flow Hepa filtration, empty bottle sterilization, Ultra-Violet sterilisation of the caps and bottle necks.

Different line designs are supplied to suit customer requirements (eg. Glass/PET/Aluminium combi-lines).

The hot fill system typically used for various types of beverages such as fruit juice, isotonic sport drinks and teas, utilizes product recycling between filler and flash pasteuriser or external recycling tank, and special design filling valves to enable keeping a constant product temperature during the filling process.

Product is filled into either Heat-Set PET, glass and heat resistant cans.

Depending on the requirements, the line is provided with bottle turnover system for cap sterilisation followed by a cooling or pasteurising tunnel.

All contact parts and circuits are designed to enable a thorough CIP (Cleaning In Place) process.

The Hot Filling line is of course suitable also for cold fill products.

Complete projects including syrup production, high precision flavour dosing & mixing systems for the production of soft drinks, alcoholic mix beverages, energy drinks and similar products packaged into PET, Glass & Cans.

Framax supplies customized solutions to cater for each of the above mentioned product process requirements, such as counter-pressure filling, pasteurising or warming, labelling using an extensive range of the most modern and cost saving labelling techniques, followed by packaging loose or clustered packs into boxes or shrink wrapped bundles, etc.

Soft drinks like coffee, kombucha, coke, kvas.

A variety of filling systems for dense products such as edible oils are available for filling various types of containers from glass bottles to PET and cans, ranging from the high vacuum filling system to positive pressure filling, volumetric piston filling, net weight filling and flowmeter system.

Such versatility enables us to supply filling lines capable of processing a vast range of different bottle designs commonly used for “boutique” olive oils, as well as the traditional packaging. Framax can supply customers with a tailor made solution from small semiautomatic equipment to the high speed bottling and packaging lines.

Consisting in the production of sparkling wine by means of wine re-fermentation through the introduction of selected yeasts and sugar. In this way the wine acquires the traditional natural carbonation produced by the second fermentation.

After a rest period the bottles are placed up side down on special stands for the “remuage” phase, where the bottles continuous rotation allows the exhausted yeast to settle into the bottle neck.

Framax supplies equipment ranging from the simplest semiautomatic machines to fully automatic complete lines to carry out the operations of neck freezing, disgorging, dosing & levelling, as well as programmable automatic “remuage” systems.

“Ultra clean” technology for cold filling of fresh milk, yoghurt and fresh juices using electronic flow-meter or weight filling systems, which ensure the maximum product protection suitable for filling fresh products and those requiring Extended Shelf Life.

Depending on the requirements, the process includes sterilization of the containers through the use of peracetic acid or hydrogen peroxide, an intermediate holding time, sterile water rinsing, non contact filling and closing with previously sterilized closures.

All under protected environment with laminar flow Hepa filtration.

Filling technologies for cans, bottles and kegs production

Our range of can filling machines feature mechanical or electro-pneumatic filling technologies, starting from the smallest entry-level solution for micro breweries up to high speed canning for industrial breweries.

Washing sterilizing and filling machines for kegs from 10 to 50 liters capacity, available in semiautomatic version with single head and fully automatic with multiple-head.

Manifactured on a solid basement entirely made of stainless steel AISI 304 while all product contact parts and service valves are made in AISI 316.

Accurate filling volume guaranteed by volumetric flowmeter.

ModulBlock range of machines feature the possibility to supply tailor-made solutions, enabling to combine rinsing, filling and closing technologies in one machine.

The necessity to reduce the environmental impact of non-returnable bottling systems led Framax to propose an eco friendly solution offering the possibility of using returnable bottles.

Catalogue Download

Enter your details to download the Catalogue

Some of our bottling lines

Decades of experience in the beverage and packaging industry as well as prompt feedback and enthusiasm have matured in Framax gaining a good reputation from customers worldwide, trusting us as a reliable supplier of turn-key plants, from project planning, manufacturing, installation, start up and commissioning.

Ask for a free consultationor more information

We will accompany you during all phases of your project. We will always be responsible for the entire Line and the Machines that make it up.

QUICK RESPONSE GUARANTEED

(usually within 8 hours)

Your Partner in the world

Bottling and packaging technologies since 1993

Framax specializes in the supply of machinery and complete “Turn Key” production lines for the bottling and packaging industry, covering primarily the beverage field but also catering for special needs in the food and chemical sectors.

Our main objective is to provide Customers promptly with a custom-made solution, specifically designed to protect and guarantee the quality of the finished product with the use of the highest and most up-to date technology.

FRAMAX UK

Threefield House

Threefield Lane

Southampton SO14 3LP

United Kingdom

FRAMAX ITALY

Via Marlianese 31 51034

Serravalle Pistoiese (PT) Italy

+39 0573 51435

info@framax.com

FRAMAX JAPAN

1-15-608, 6 chome Gokoh dori

Chuo-ku, Kobe

651-0087 Japan

In a short time you will have a tailor-made bottling line, tested and performing with an always active after-sales service.

Don't miss this opportunityCONTACT US NOW!

© Copyright FRAMAX S.r.l. | P.IVA: 01184350476 | Privacy Policy | Cookie Policy | Web agency: Campbell Adv